EVERYTHING ABOUT CONCRETE BATCHING PLANT

Concrete batching plant is a concrete production line for the purpose of providing raw materials for infrastructure construction or commercial, semi-finished concrete.

Manual mixing or mixing with concrete mixer can satisfy small-scale projects. But to meet large-scale construction projects, it is necessary to use a concrete batching plant with a large capacity mixer, producing a large amount of concrete to meet the construction progress.

Fresh concrete batching plant has two main types: stationary batching plant and mobile batching plant

Fixed concrete batching plant is a type of batching plant built at a fixed location, usually used by commercial concrete companies or concrete pile manufacturers. Mixing plants have different capacities such as: batching plants with capacity of 30m3/h, 45m3/h, 60m3/h, 90m3/h, 120m3/h…

Mobile concrete batching plant is a type of batching plant that can move from one place to another to serve construction projects in many different locations, often used to serve short-term projects.

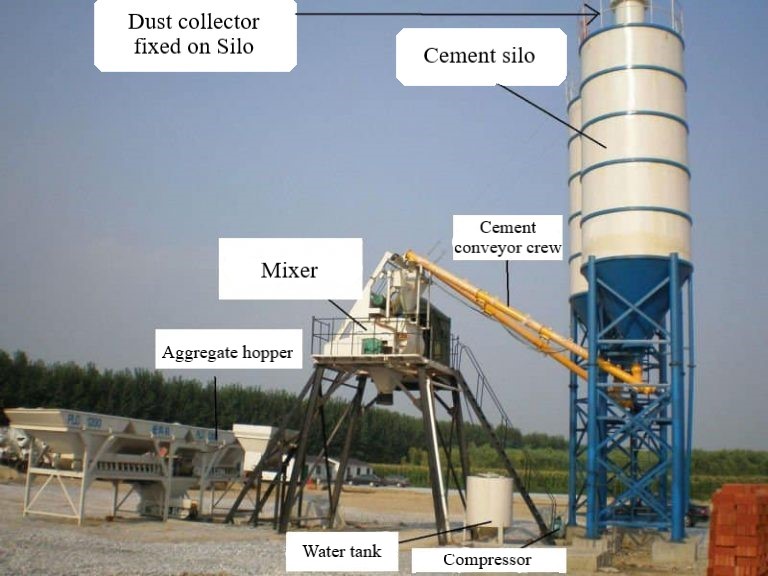

Structure of cement concrete batching plant:

- Material supply department

It is a place to store raw materials: stone, sand, gravel, cement, and other additives that are gathered outside before being put into the mixing bowl. The materials are stored separately in the feed hoppers, when running, the machine will calculate the right amount of material according to the command from the central control station. After weighing the materials, they will be transferred to the mixing bowl by conveyor or winch.

- Dosing system

Used to weigh and measure the weight of materials according to the volume of the mixer or according to a standard ratio to give quality and standard concrete batches.

- Concrete mixer

Like the "heart" of the batching plant system, the concrete mixer or the mixer will do the main task of mixing all kinds of materials together according to the specified formula, to produce batches of concrete. commercial products of the required quality. For each capacity level of the batching plant, different types of mortars are used.

- Control system

Control systems are classified into three main categories: electric drive control, pneumatic drive control and hydraulic drive control. This control system will help the batching plant open and close the discharging doors as desired.

- Steel structure system

It is a bearing structure system that supports the entire system of the batching plant, including traffic corridors, mixers, feed scraps, cement silos, etc.

Working principle of cement concrete batching plant

- Feeding process for the batching system: Cement is stored in silos, sand, stone, gravel is transported by conveyor or winch to fill the feed hoppers.

- Next, the operator needs to set the parameters of the feed rate into the automatic control system. At the beginning of operation, the system will take in materials according to the predetermined ratio. Then the material is put on the mixer, where the sand, stone, gravel, cement and additives are mixed with water. Under the operation of the concrete mixer to create the right quality concrete batches as required.

Where should I buy a concrete mixer?